Background

With the continuous advancement of modern medical technology, the performance requirements for wound management and tissue repair materials are steadily increasing. Traditional dressings often suffer from poor adherence, limited breathability, and low healing efficiency, making them inadequate for complex wounds or chronic ulcers. At the same time, the field of tissue engineering urgently requires high-performance, biocompatible, and structurally tunable scaffold materials to support cell growth and tissue regeneration.

In this context, MCC/alginate composite hydrogels—developed through natural polymer composite technology—have emerged. Combining mechanical strength, biocompatibility, and the ability to maintain a moist healing environment, they represent an ideal new-generation material for wound dressings and tissue engineering scaffolds.

Product Introduction

Product Name: MCC/Alginate Composite Hydrogel (Research & Medical Grade)

Overview:

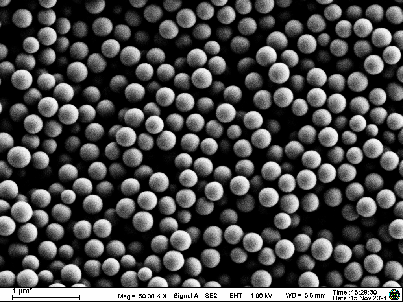

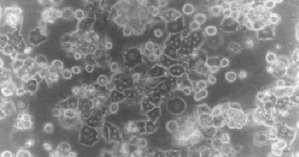

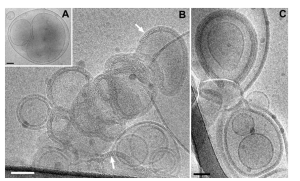

This product is formulated by combining microcrystalline cellulose (MCC) with natural alginate to form a composite hydrogel. It offers excellent moisture retention, film-forming capacity, and controllable degradability, making it suitable for a wide range of applications in wound dressings and tissue scaffolds.

Technical Parameters:

- Water content: ≥90%

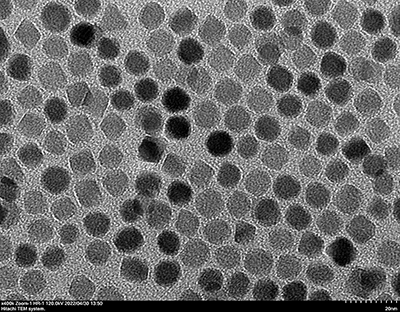

- Porosity: 50%–80% (adjustable)

- pH stability: 6.8–7.4

- Biodegradation period: 1–3 weeks (customizable based on application)

- Sterility: compliant with medical dressing standards

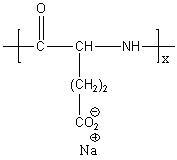

Composition:

- MCC (Microcrystalline Cellulose): provides structural reinforcement and mechanical strength

- Sodium Alginate: forms a flexible network structure to maintain hydration

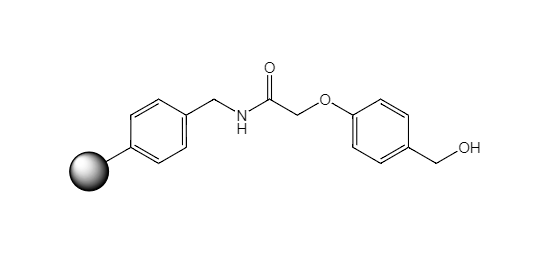

- Optional Additives: antimicrobials, drug molecules, growth factors, etc.

Physical Properties:

- High tensile strength and flexibility

- Excellent film-forming and wound adherence capacity

- Good gas exchange and water vapor permeability

Customization:

Taskcm has established a mature hydrogel preparation platform, supporting the entire workflow from raw material selection and formulation development to functional enhancement. We provide customized solutions for viscoelasticity, pore size, and release profiles to ensure precise performance matching for diverse applications.

Product Advantages

Performance Benefits

- Rapid absorption of wound exudates, maintaining a moist environment

- Inhibition of bacterial invasion, promoting faster healing

- Excellent adherence to wound surfaces without secondary damage

Core Functions

- Wound dressings: for burns, pressure ulcers, diabetic foot ulcers, and other chronic wounds

- Scaffold materials: for skin, soft tissue regeneration, and bone tissue engineering support

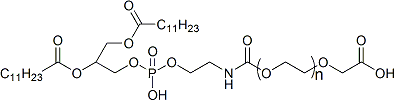

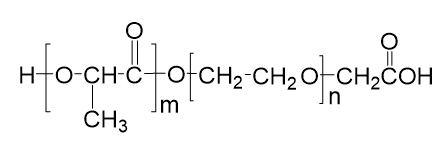

We also provide drug encapsulation solutions, enabling the hydrogel system to load small-molecule drugs, bioactive factors, or antibodies, combined with drug modification and antibody conjugation technologies to enhance local stability and controlled release.

Comparison with Alternatives

Compared with single-component alginate hydrogels or synthetic dressings, MCC/alginate composite hydrogels offer superior strength, controllable degradation, and higher drug-loading capacity, making them more adaptable and user-friendly in clinical practice.

Economic Advantages

- Renewable raw materials with stable supply

- Cost-effective and available in multiple customized specifications

- Mature production processes enabling scalable industrial translation

Cost Efficiency

By improving drug utilization and wound healing efficiency, this material reduces the need for repeated treatments and lowers the incidence of complications—ultimately decreasing overall treatment costs.

Application Scenarios

Primary Applications:

- Medical wound dressings

- Chronic wound care (e.g., diabetic ulcers, pressure ulcers)

- Skin substitutes and tissue scaffolds

- Regenerative medicine research platforms

Case Example:

In a burn wound dressing project, MCC/alginate composite hydrogels loaded with antimicrobial peptides and epidermal growth factor significantly accelerated skin regeneration in animal models. Healing time was reduced by approximately 40%, and repair quality was superior compared to conventional carboxymethyl cellulose dressings.

Taskcm has achieved standardized production and pilot-scale capability, with an annual output capacity of several tons of composite hydrogels. This ensures stable supply and supports smooth transitions from research to industrial-scale production.

Implementation & Customer Support

Implementation:

- Design phase: customized hydrogel size, drug-loading capacity, and release profile to match specific microenvironments

- Manufacturing: advanced self-assembly and nanofabrication processes to ensure stable quality, scalable from pilot to large batches

- Application: tailored hydrogel adaptation solutions for integration into wound care or tissue engineering systems

- Maintenance: single-use biodegradable materials requiring no complex upkeep, storable long-term and convenient to use

Customer Support:

- Technical support: end-to-end consultation from formulation design to performance optimization, ensuring smooth translation of functional requirements

- Training services: application training, wound care demonstrations, and research project alignment to improve customer efficiency and outcomes

- After-sales service: batch traceability, performance verification, and upgrade recommendations to ensure ongoing adaptability for clinical and research needs

Conclusion

MCC/alginate composite hydrogels—through their structural advantages, biocompatibility, and functional versatility—have emerged as a high-potential material in wound care and tissue engineering. Whether for chronic wound management, regenerative scaffolds, or innovative drug delivery platforms, they offer wide application prospects.

With continually improving production processes and scalable manufacturing capacity, Taskcm is committed to providing high-quality hydrogel products and one-stop services, helping clients accelerate the clinical translation of regenerative therapies and shaping a more intelligent and healing future for healthcare.